21 Years of Industry Experience - SA Owned & Operated

Same Day Equipment Delivery Available -

Open 7 Days!

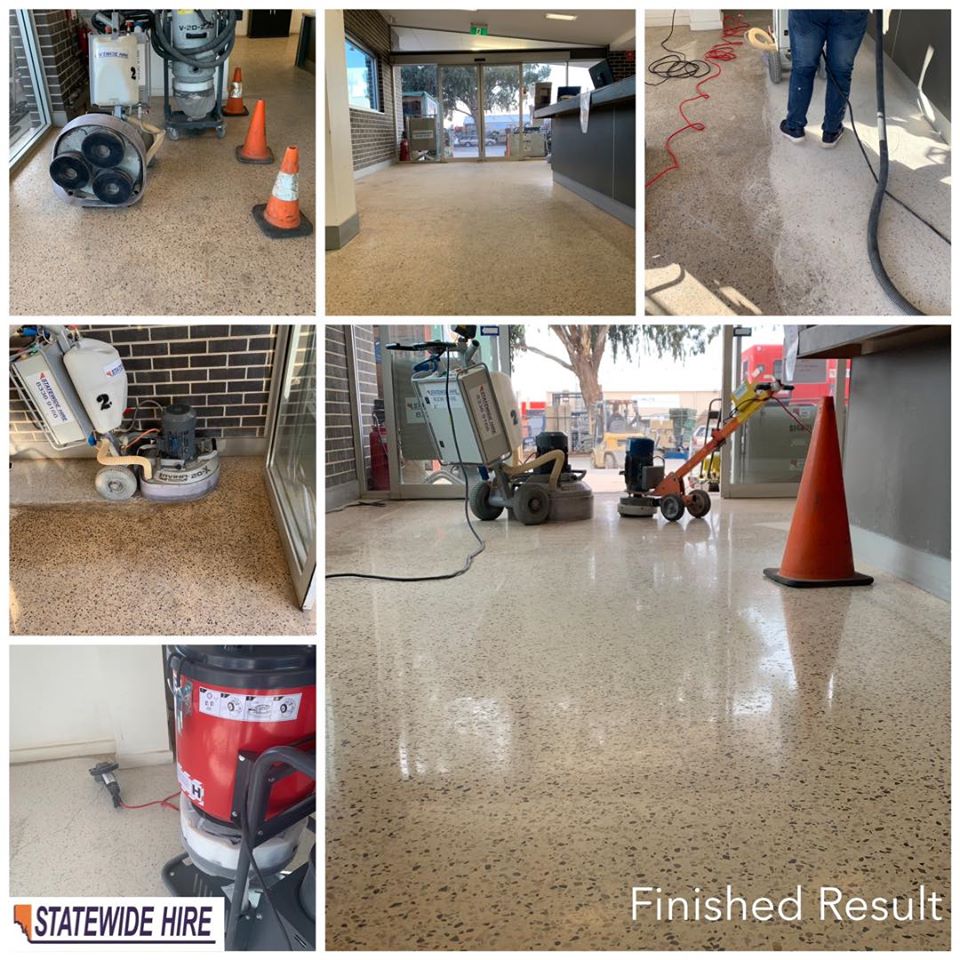

How to Grind & Polish your floors with our Lavina 20 Floor Grinder

How to Grind & Polish your floors with our Lavina 20 Floor Grinder

Who are Superabrasive?

Superabrasive established in 1987 when they began manufacturing diamond tools. They now have a huge variety of products for concrete grinding, polishing, stone fabrication and optical lens edging.

Superbarasive Lavina line which we will be focusing on, have an extensive range of Concrete Grinding & Polishing machines & diamond tools to help with all aspects of your job from surface prep to high end polishing.

We will be taking a deeper look into our Superabrasive Lavina 20 Floor Grinder machine and take you on a journey to discover the all the tips and tricks of the trade to get your floors looking incredible!

Watch Our Youtube Channel Videos Here:

https://www.youtube.com/@statewidehire8732

Learn More About LAVINA Here:

https://youtu.be/0nq7RwSicpQ

See The LAVINA Step By Step Guide Video Here:

https://youtu.be/_tKaObUNIHk

What you need to know before starting?

Depending on your experience with concrete grinding and polishing you may already know a lot or you may be at zero, starting from scratch & we are here to help.

Let’s start with the different types of diamonds segments & polishing pads you need to know. The general rule is with concrete grinding & polishing, you’ll be starting the process with a coarse, metal bonded diamond disc or shoe and by the end finishing with a smooth polishing pad. ‘Grit’ is the term used for the coarseness of the diamond disc and the higher the number will result in a smoother, polished finish.

Floor Preparation

Firstly, before starting to prepare your floors, make sure you take all safety precautions including wearing a mask, protective clothing, googles & ear plugs. Now that you’re set let’s begin..

The first step is to make sure you’re starting with a clean surface by removing all debris and dirt from your floors.

Secondly, Use the Lavina 20 to prepare the surface. Grind the concrete floor to remove coatings and smooth out the area of any imperfections or bumps.

Thirdly, ensure you fill in any gaps or cracks that may be present in the floors with a cement based product.

Wet Or Dry?

Before you begin, it’s time to decide on which method you are going to use. In the world of concrete grinding there are two primary approaches to choose from.

The first and most popular type is the Dry Method. Dry concrete grinding is more environmentally friendly, easier to keep clean with our Pullman Vacuum and you can see the results immediately during the grinding process.

The Wet method to concrete grinding is the more traditional method of the two. Though you won’t have to worry about dust, it can make a lot of mess and you’ll need to worry about cleaning up the slurry left behind on both the floors and Lavina 20 Grinder, but a positive is it will cool down your diamond tools and reduce wear and friction.

The Concrete Grinding & Polishing Process

Now that your floors are clean, exposed and filled of any cracks, it’s time for the fun to begin!

STEP 1: GET GRINDING

Grab your Lavina 20 and begin the concrete grinding process. Make sure to keep in mind when selecting your grits, using a lower numbered grit will result in a coarser grind, and higher grit will leave you with high smooth finish. Generally you’d begin with a 30 diamond grit.

When grinding move the Lavina 20 in circular movements making your way from one side of the room to the other. Do this carefully to ensure you don’t miss any floor area.

Depending on the finish you are after, continue this process using a higher grit each time (70, 120) to achieve the results you desire.

STEP 2: LET’S HARDEN UP (Optional)

Now it’s time to apply a chemical hardener of your choice.

This will assist in setting and strengthening your concrete, whilst providing protection from staining, damage and wear. It will also allow for a high sheen result.

Let the hardener dry before continuing on with the polishing process. You should allow up to 1 hour drying for lithium products and 12-15 hours of drying for potassium products.

STEP 3: POLISHING TIME

Next, we use our Lavina 20 with high grit diamond polishing resin pads and pass by covering all your concrete area. This grits you’ll be using will range between 60 – 3000 grits. The higher grit you use, the higher the sheen.

Once you’ve completed your polishing process, you want to use our vacuum system to rid of all dust particles before then passing over once last time a finishing pad with the Lavina 20 to give a buffed, smooth, high gloss finish.

Sealers are a personal preference. Please do some research on your preferred products.

STEP 4: TIME TO SEAL

Using a concrete sealer of your choice, apply with a spray or roller. Let dry for approx 2 – 4 hours, reapply sealer a second time, then repeat the drying process. Sealers should be followed by recommendations of the manufacture.

Sealers will provide a smooth and buffed finish and shield your concrete from chemicals, oil or dirt.

Download The Step By Step Guide PDF

What can I hire from Statewide Hire & what is the process?

At Statewide Hire we can provide you all the equipment needed to Polish & Grind your concrete including the Superabrasive Lavina 20 Floor Grinder, diamond segments, and polishing pads.

We offer daily or weekly rates.

You can call our friendly staff on (08) 8336 9166 or visit us in store at 32 Papagni Ave, Newton, 5074.

We are happy to assist with any questions or guidance you may need.